The tyre and the wheel together form the complex structure that supports the weight of your vehicle. These tyres and wheels thus have to be very symmetrical, not only in structure but also in weight distribution in order to rotate flawlessly. This is where wheel balancing comes in. Wheel balancing is a procedure where such differences in weight distribution of the wheel as well as the tyre are corrected with the help of weights.

This is done as any difference in the distribution of mass in the wheel and tyre combination will result in vibrations, mainly due to the periodic changes in force and torque while the wheel rotates.

There are essentially two ways in which wheel balance is checked:

1. Traditional Spin Balancing :

The traditional spin balancing utilises a simple spindle on which the wheel is mounted through the centre bore which spins the wheel at a very high speed. The wheel is held firmly at its place with the help of a metal cone which helps in perfectly centring the wheel. The machine is able to determine the heaviest points on the wheel and how much weight should be placed on the opposite side to balance it out.

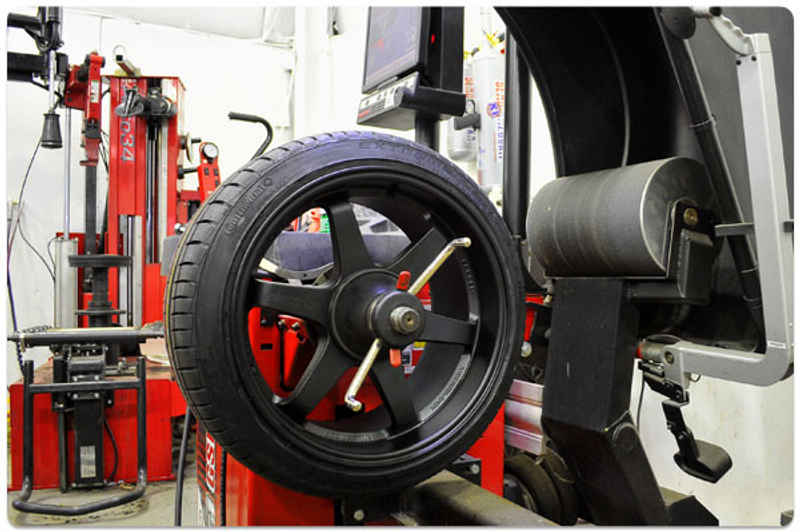

2. Road force balancing:

Road force balancing physically examines the wheel with the help of a large roller that spins against the tyre. The roller is sensitive to things like tyre pressure and radial runout and is able to identify spots which would produce any vibrations on the road. It is in fact so capable that it detects belt separations and match mounting issues as well. The road force balance also performs a spin balance but has a ton of extra features that give more information about the tyre.

Also See: Tyre Maintenance 101: Your Bible For Longer Tyre Life

A very important thing to note is that wheel balance changes over time and an imbalance is extremely common. Uneven tyre wear is something that contributes significantly to wheel imbalance as lesser tread at places will mean lesser weight. This is very common since perfectly even tyre wear is nearly impossible to achieve. We don’t drive perfect and hence neither will our tyres wear perfect. Thus, it’s important that you get your wheel balancing done regularly after every 3000-4000 km or every time you rotate your tyres.

Types of weights used to correct imbalances:

Band on weights

Bang on weights are made of lead with soft lead flanges that are fitted between the tyre and the steel wheels. These worked great during earlier times when steel wheels were not clear coated.

Adhesive weights

Adhesive weights became essential as alloy wheels came into existence. The bang-on weights used earlier scratched the clear coat on these wheels which exposed the aluminium and paved the way for corrosion.

Adhesive weights are simpler and do not need to be hammered anywhere. They are flat strips of lead weights with an adhesive at their back. These weights are square-shaped with a standard weight for different squares and are placed inside the barrel behind the spokes of the wheel.

Although the adhesive on these weights is quite strong, we recommend that you ask the mechanics to clean the surface before they use the weights. This will make sure that the surface is free of any dust or oil that can compromise the adhesiveness of the weights. You can also ask the mechanic to use some duct tape as an additional reinforcement to keep the weights in place.